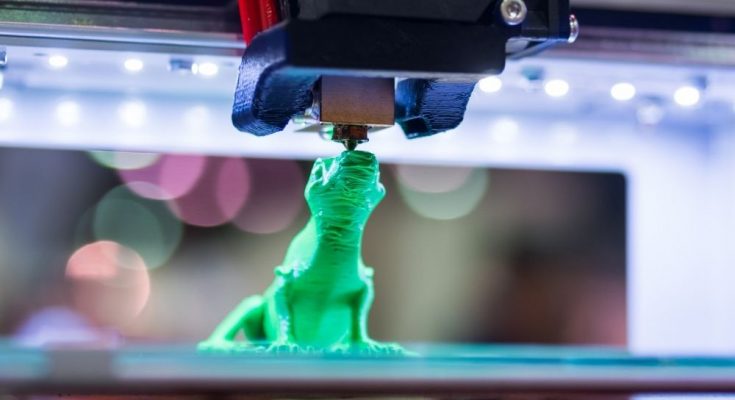

3D printing is one of the most reliable and accurate ways to create seamless models and prototypes on the first try. With hundreds of high-strength, high-resistance materials, there’s seemingly no end to the possibilities of this technology. However, even the best 3D printers can make a few errors, and knowing how to mitigate risks can ensure you’re producing exactly what you want. This is how to troubleshoot common 3D printing problems and some warning signs to be aware of.

Part Warping

The first common issue to watch for when 3D printing is warping. Warping happens when your printing material experiences a sudden change in temperature, causing the top layer to split off and bend. This not only affects the look of the product but also decreases its performance capabilities. Fortunately, you can greatly decrease your chances of experiencing this problem by installing a hotbed in your printer. These additions slowly bring the printing platform up to temperature, so the material has time to properly adjust.

Over or Under Extrusion

You may have also experienced over or underextruding during your 3D printing projects. Extrusion is the process of pushing material through the printing nozzle and placing it according to the designated blueprints. Though, in some cases, the material can leave the nozzle slower or faster than needed, creating issues with the result. If you find your printer is over or underextruding filaments, check your printer’s settings. Adjusting the registered size of your nozzle and filament diameter can often mitigate the problem.

Delamination or Cracking

3D printed parts consist of several filament layers that all bind together to form your model. But, if your printer can’t maintain the proper printing temperature, you might discover some of these layers have failed to join correctly. Delamination weakens the entire component and makes it harder for it to serve its intended purpose. So, following this error, it’s vital that you repair your printer’s printing bed immediately. We also recommend purchasing high-quality printing filaments that are better at joining together in the printing chamber.

Stringing

Another common 3D printing problem to troubleshoot is stringing. This issue occurs when your printer’s hot end drips additional plastic as it moves. It’s characterized by its series of thin strands on your printed model which tarnish the clean aesthetic you wanted. This is a simple fix, though, as you only need to replace the hot end to stop this from happening.

Additional Resources: