When choosing a manufacturing process for your product, a high degree of design flexibility should be a top priority. Ultimately, design flexibility can have a large influence on the function, aesthetic appearance, and overall success of your final product. To gain a better understanding of what design flexibility is and why it is important, continue reading.

In the manufacturing industry, design flexibility largely refers to the ability of a production process to quickly and efficiently accommodate internal or external changes. Design flexibility may also refer to the freedom that a given design process grants the designer in terms of implementing various capabilities.

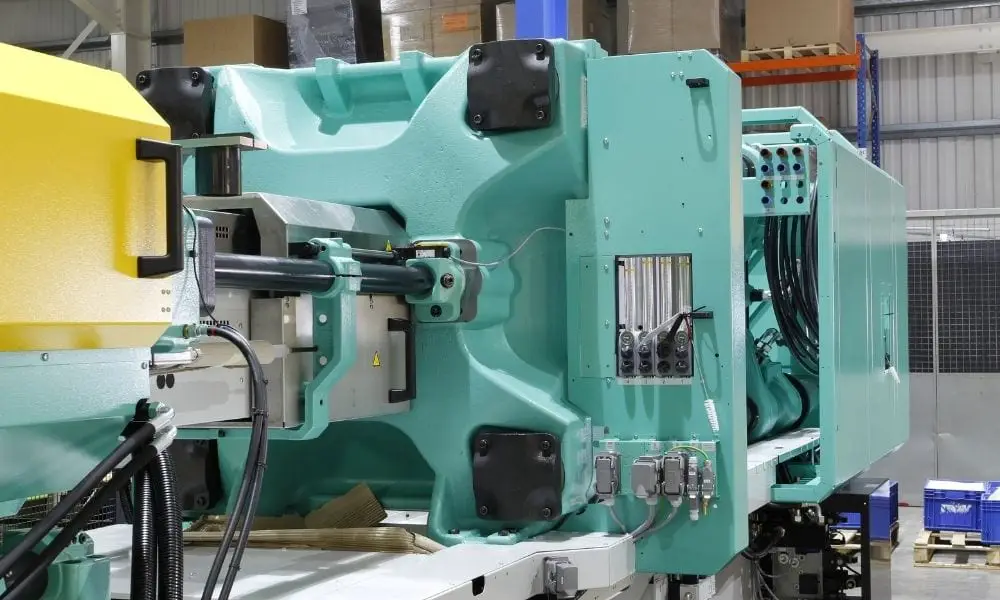

For example, the process of reaction injection molding is considered to offer a high degree of design flexibility due to its many different capabilities, such as encapsulating materials, molding in attachments, creating parts with high variations in wall thickness, and inserting stiffening ribs. Such competencies allow designers the flexibility to create a diverse range of designs without compromising aesthetic or functional features due to design limitations.

Now that we have discussed what design flexibility is, let’s move on to why it is important. As previously stated, the level of design flexibility that a manufacturing process offers can largely influence the success of the final product it is used to produce. Some of the most notable advantages of design flexibility include:

Understanding the common causes of delays during facility relocations can save you time, money, and…

If you or someone you know suffers from sleep apnea, chances are a CPAP (Continuous…

Learn about four effective methods hospitals can implement to share patient status updates, ensuring clear…

Learn about the benefits of an organized outdoor shed. Discover easy methods to reduce clutter…

Want to fly multiple flags but are worried it might be disrespectful? Here’s what you…

Prepare for power outages with tips on staying warm, safe, and stress-free. Learn how to…