Many people don’t realize how prominent metal fabrication is in our daily lives. However, if we stop to look around, we would recognize that metal fabrication is all around us. We shouldn’t take the industry for granted. There are so many different applications of metal fabrication, and this piece will touch upon a few.

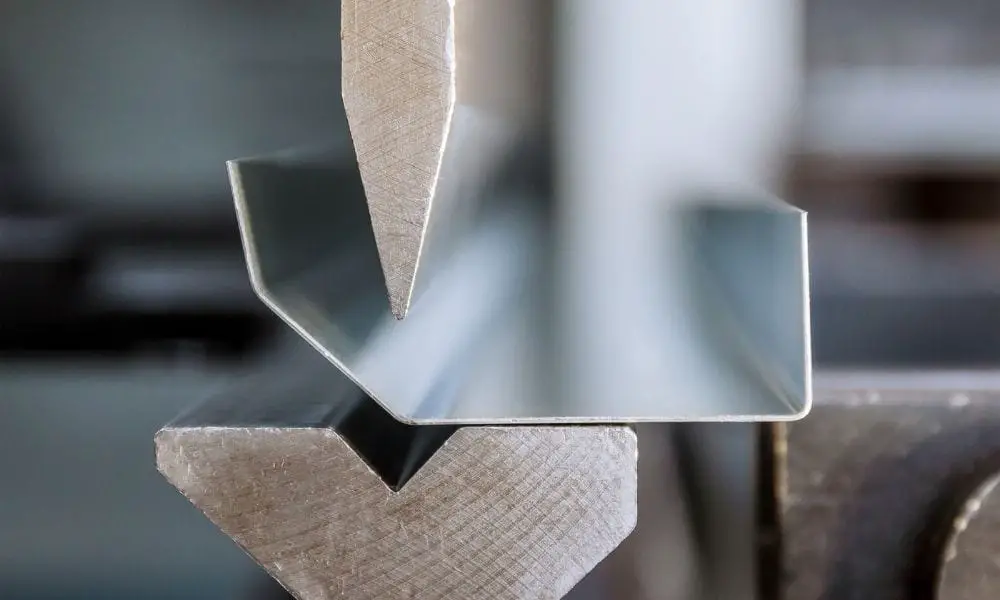

Before the COVID-19 pandemic, many of us went into office buildings every day. Still, not many people put much thought into how the building was constructed. The truth is, metal fabricators play a huge part in creating the buildings in which we spend the majority of our time. Metalworkers create angles on pieces of sheet metal to put a building together. Without their hard work, we wouldn’t have the skyscrapers that are a staple of modern times.

Unfortunately, people are not really traveling on airplanes this year. Perhaps, this time on the ground has given all of us time to think about how airplanes are constructed. Much like buildings, airplanes wouldn’t exist without the help of a metal fabrication shop. Airplanes are incredibly intricate; they require specifically designed parts to function correctly. Trained professionals are needed to ensure that every plane in the sky is safe as can be. That’s why aerospace manufacturers consult metalworkers on a daily basis.

We can’t talk about planes without talking about cars. The automotive industry is perhaps the largest partner of those in the metalworking field. Metalworkers use devices like plasma cutters and structural steel fabrication machinery to design the vehicles we drive every day. Engineers would be lost without fabricators because sheet metal is not their expertise. The reality is, these businesses must work together to ensure the drivers have the cars they want.

There are many different applications of metal fabrication that this article hasn’t even touched on. In fact, the industry is so expansive it requires further study. If you are interested in knowing how present this field is in our daily lives, try to do further research on the matter. You may be surprised at what you discover.

Unfortunately, people are not really traveling on airplanes this year. Perhaps, this time on the ground has given all of us time to think about how airplanes are constructed. Much like buildings, airplanes wouldn’t exist without the help of a metal fabrication shop. Airplanes are incredibly intricate; they require specifically designed parts to function correctly. Trained professionals are needed to ensure that every plane in the sky is safe as can be. That’s why aerospace manufacturers consult metalworkers on a daily basis.

Optimize your food processing facility by better understanding the critical ways gases can impact electrical…

Discover the best safety practices for restaurants, ranging from fire prevention to hygiene standards. Take…

Radon levels rise at higher elevations due to low air pressure and sealed homes. Learn…

There’s nothing worse than lighting a new candle and watching it sputter out, tunnel, or…

Discover how woven metal fabric transforms restaurant design with its versatility, from feature walls to…

Upgrading your workspace? Get inspired by design ideas for materials, lighting, and amenities, and tips…