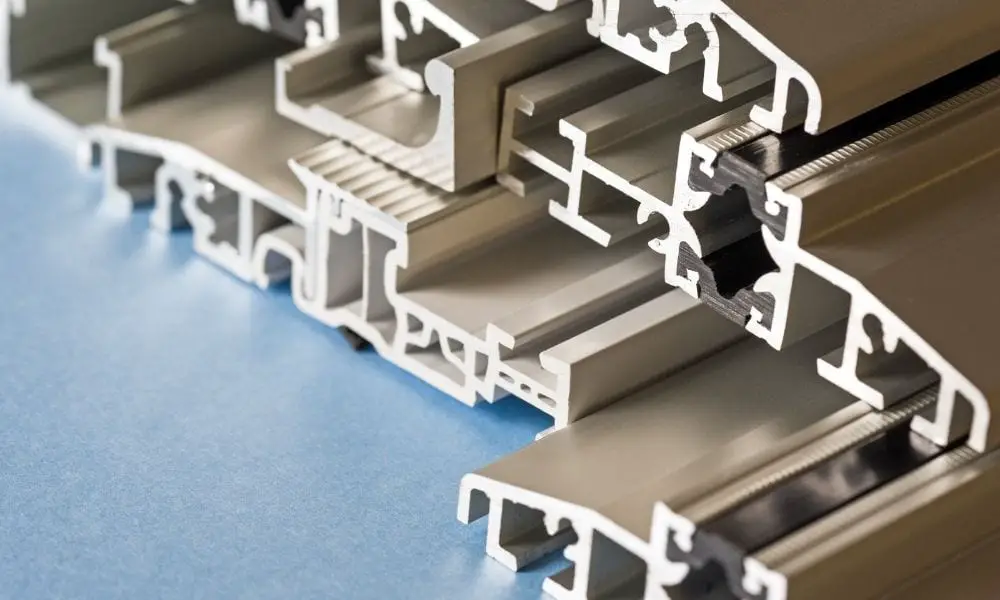

When most people think of aluminum, they usually picture foil instead of common industrial applications. Billets are large cylinders of aluminum. Experts can design custom-built materials by warming up aluminum billets and forcing them through a specially shaped die.

Even if most of that description was gibberish to you, almost everyone encounters aluminum extrusion regularly. The technical breakdown of aluminum extrusions can prove daunting to newcomers. Reading these surprising everyday uses of aluminum extrusion will provide a better context for what this process is and why you benefit from it.

Any handrail you encounter throughout the day is likely an aluminum extrusion. Whether in someone’s house or at a company’s office, aluminum extrusion is the go-to method for building railings. One benefit of aluminum is its strength-to-weight ratio; it’s a relatively lightweight metal but remarkably durable. An aluminum extrusion provides the reliable performance and durability support systems like guardrails require. Even many hospital bed frames are aluminum extrusions.

Yes, even the desk you work on at the office is most likely an extrusion. Manufacturers can use aluminum extrusions for modular designs. A modular system comes in multiple parts you can easily assemble, so these materials are popular for desk building. Plus, manufacturers can build modular systems to make them easy to upgrade.

On top of its strength and weight, two of aluminum’s top benefits are its heat and electrical conductivity. This opens the doors for even more technical applications. For example, lighting fixtures are a widespread use of extrusions. Your everyday desk lamp or bedside lamp is utilizing extrusions right in front of you. And this practice isn’t going out of date anytime soon; modern LEDs use aluminum extrusions for the same reasons. However, electrical applications go beyond lighting fixtures—medical devices also utilize aluminum extrusion components to work properly.

As you can see, there are quite a few surprising everyday uses of aluminum extrusion. If you ever need a metal fabricator to build workplace equipment and they start talking about extrusions, you’ll know what they mean. By following the right steps when searching for aluminum fabricators, you can find the perfect avenue to build office materials. However, if you don’t take the time to find a reliable service provider, results will definitely vary.

Discover the best water valve materials for your plumbing needs. Compare brass, PVC, CPVC, and…

Consular processing helps individuals achieve their US immigration goals efficiently. Learn about the advantages of…

Reliable equipment is essential for construction, mining, and more. Learn why lubrication matters for heavy…

Heavy equipment is essential on many construction sites, and enlisting the help of professional storage…

Action movies, documentaries, and more benefit from filming in the middle of natural landscapes. Explore…

Learn how to create spotless, functional restrooms with routine inspections, quality tools, and prompt maintenance…