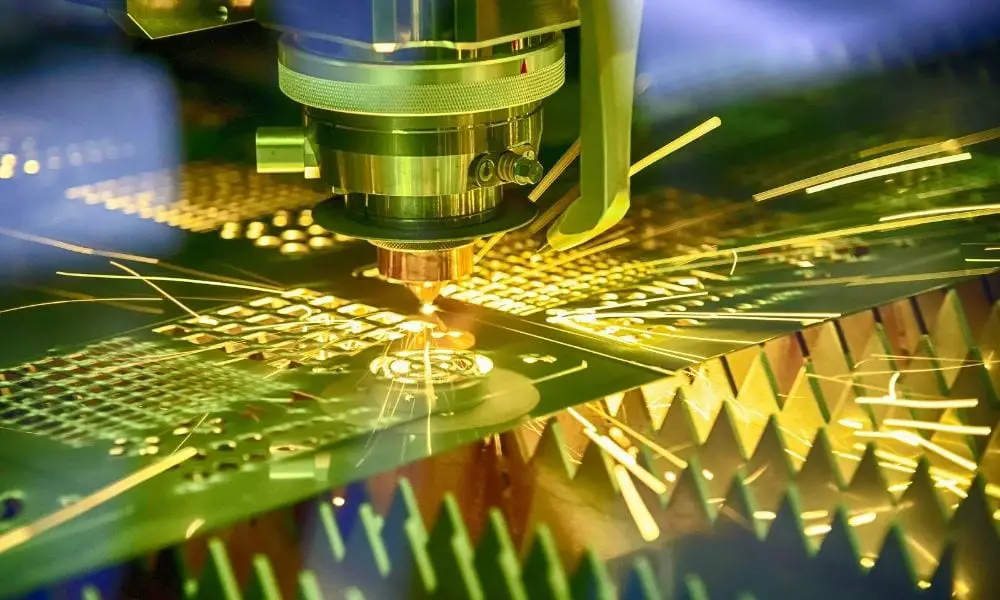

Fiber laser cutting has made the work of cutting metals and non-ferrous products tremendously easy. Fiber laser cutters are the most efficient way of laser cutting. They have a strong airflow leaving little room for error. They’re efficient and lightweight and help shops increase revenue streams because workers can complete more jobs in less time. However, they’re very complicated machinery, and mistakes can be made. Read on for mistakes to avoid with fiber laser cutting.

You should always scale your drawing before you set it up to be cut by the cutting machine. The drawings help to ensure that the dimensions of your workpiece match the dimensions of your device. The scaling depends on the kind of software you’re using for the same.

Most manufacturers know that metal needs to be marked and understand that the machine doesn’t accept or detect light colors. Though there’s no specific color defined, it is recommended to use red lines because of their high visibility.

Manufacturers often rely on high wattage to increase the speed of cutting their metal. Other factors can significantly affect the rate of your cutting. The efficiency of the optical system of your laser cutting machine also determines the speed of your work. By improving how the laser cutter focuses on the beam, you can speed up your work without incurring higher energy costs.

Some laser cutting machines can work on ordinary shop air during operation. A compressor set up in the workspace provides the air to this machine. Some manufacturers increase their costs by employing separate compressors for laser cutting. Instead of spending extra on a compressed air system, you can supply hose to another compressor that supplies air to other machine shop areas.

Workers often show carelessness while moving material from the laser cutting machine. A slight movement can hit the head and cause damage to the machine or can knock the laser head out of alignment. While these are small things, they’re worth noticing to avoid damage.

Hopefully, you’re now aware of mistakes to avoid with fiber laser cutting. With these tips,you can continue to run your shop safely and efficiently.

Want to bond over unexpected activities? Look at these unconventional ways to connect with your…

Burnout isn’t just something that happens to CEOs. For moms homeschooling littles, it’s a very…

When it comes to long-distance motorcycling, comfort, reliability, and smart engineering can make or break…

Flowers have seen significant transformation over time; online flower shopping is increasingly common now for…

Learn essential first-time landlord tips for success, from tenant screening to property maintenance. These strategies…

Every business will produce some form of waste. The real task isn’t preventing waste entirely—it’s…