There are few more stunning ways to grab a customer’s attention than with glints of metallic gold or silver radiating off a product package. Adding foiling and highlighted areas of text with embossing really makes a brand, slogan, or product information pop. This seemingly simple touch is a very old tradition used by printers as far back as the 19th century.

Over the years, it has also evolved quite a bit. There are now many techniques and approaches to create hot stamp printing. This includes advanced machinery that simplifies the process quite a bit. Despite the wonders of technology, many of us are still curious and ask, “How does hot stamp printing work?”

What Is Hot Stamping?

We are all familiar with how a stamp works—simply take your stamp and ink, and stamp away. Hot stamping is not too far off from this idea, though the tools generally have advanced quite a bit from the small handheld found in most stationery shops. The original process evolved from this, using metal-cast stamps to emboss and transfer.

In hot stamping, the goal is not to make a necessarily deep impression as with embossing. Instead, the metal stamp is heated. When a foil is introduced, the heat helps to adhere the material onto the page or product.

The Different Tools of Hot Stamping

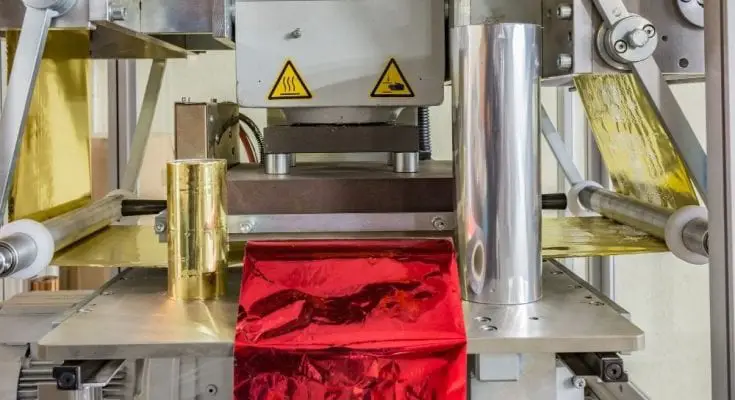

“How does hot stamp printing work?” is a question that can depend greatly on the tools being used. This art has evolved greatly since the olden days. Now, it is very easy to find advanced machines that virtually automate the process. In high production hot stamping, very large printing is used in conjunction with computers to digitally design and print stamped objects very quickly. Many companies even offer hot stamping services to businesses seeking innovative product package design.

Many use lasers to create very precise images without needing to produce and apply a unique die for every design. Similar home-printer sized hot stamping units can be found commonly in craft stores. For the traditionalist, old fashioned handheld stamps do exist. This includes metal handles with interchangeable dies and electric handles that heat dies much like a handheld wood burning tool.

How To Hot Stamp

As the name suggests, hot stamping is not at all unlike the stamping we all know about from arts and crafts class. However, the stamp is always metal for this process unlike the various lighter alloys used in common stamps, as well as wood, ceramic, and rubber varieties. Usually, the stamp, also referred to as the die, is mounted over what is to be stamped.

The desired foil is then inserted between the die and the subject. The die is heated and then pressed into the object being stamped. The heat causes the sections of the foil to break loose and stick to the object anywhere the hot die touched. The result is a beautiful imprint of the die-cast design.